Energy is the most demanded resource of our modern civilizations. Construction concrete requiring cement is the second-most used resource. Given this combined and growing demand, we have establishment a “joint energy taskforce to manufacture optimal renewable resources” from wastes. . . referred to as “JETMOR.”

Extensive work on JETMOR has been completed by its members preparatory to seeking additional support for this public-private-partnership renewable energy project.

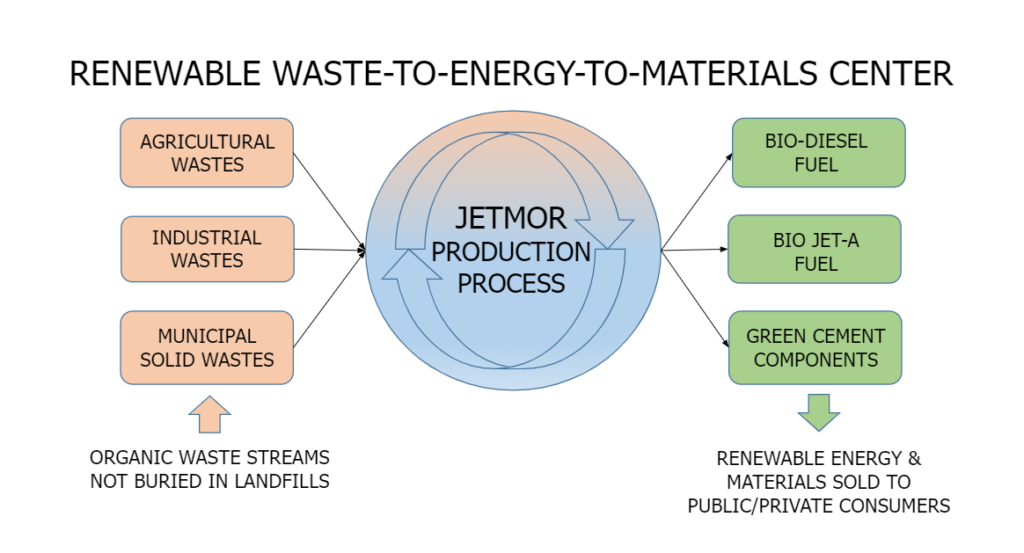

JETMOR will be a Waste-to-Energy-to Materials facility that aggregates and reforms municipal solid waste (MSW), garbage, and other strategic stone materials into (1) renewable energy in the form of aviation grade Jet-A fuels, transportation grade diesel with (2) sustainable cement production using waste calcium and biochar byproducts.

JETMOR products will be continuously needed and produced as society transitions to more efficient energy and materials usages. With JETMOR in operation, the ever-growing footprint of landfills will be minimized in the communities where JETMOR operates.

MSW is a renewable resource to create sustainable energy. Limestone for cement is a strategic infrastructure resource. Given these feedstocks, manufacturing efficiency and product stream purification is the main technical challenge confronting renewable waste-to-energy (WTE) plants. This problem has been solved by JETMOR’s founder (Jay Carlson) through industrial patents which protect its advantaged production processes and commercial viability.

As shown, JETMOR will efficiently conjoin standard industrial processes into integrated steps and unique loops to improve manufacturing efficiency of critical materials and to purify its pyrolysis gas-to-liquid (GTL) product streams.

Expandable and adaptable, JETMOR’s business model relies on a structure co-owned by cities, counties, AOGs, special service districts and Agri-Biz groups, which will transfer their daily MSW tonnage and forward their curb pickup and transfer collection fees to their jointly owned Waste-to-Energy-to-Materials facility operated by JETMOR’s general technical and sovereign members.

JETMOR will be first established in Central Utah near the optimal confluence of power lines, highways, railroads, natural gas and water lines to maximize production and minimize costs.

JETMOR is a closed loop system being self-sustained by its own outputs. Drawing upon nearby population centers, the JETMOR public-private-partnership will create numerous high-paying technical jobs in construction with ongoing operation and maintenance employment.